Create affordable living space in any part of the world with the N3P Portable Precast Plant.

The name holds the promise: NEULANDT’s mission is to enable new land to be developed in a way that transforms it into socially, economically, and environmentally valuable property – in every place, every day. The N3P Portable Precast Plant is the foundation of this mission. The N3P Portable Precast Plant was designed especially for industrial mass production of precast concrete elements on site. Its innovative butterfly technology, based on a folding steel formwork, enables efficient, sustainable, and economical construction even in the most remote corners of the globe. After all, one of the most urgent challenges of the future is to create affordable housing and living space everywhere in the world. Industrialising construction is the key to meeting this goal, and NEULANDT has laid the foundation for fulfilling it with the N3P Portable Precast Plant as its flagship solution for producing precast concrete parts directly at the construction site.

Precast concrete parts production where it’s needed: the N3P Portable Precast Plant onsite.

The N3P Portable Precast Plant makes precast concrete parts available at any location without time-consuming transport. Just use the N3P to pour, shutter, and cure concrete directly at the construction site. This efficient method of working using NEULANDT’s N3P Portable Precast Plant makes creating affordable housing and living space possible even in parts of the world where the challenges to urban planning and access to housing are greatest.

The N3P Portable Precast Plant not only produces precast concrete elements, but also promotes the training of local employees. It is also a place where stakeholders exchange knowledge on the industrialisation of the construction industry and the implementation of large-scale construction projects.

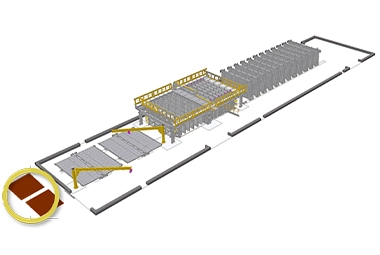

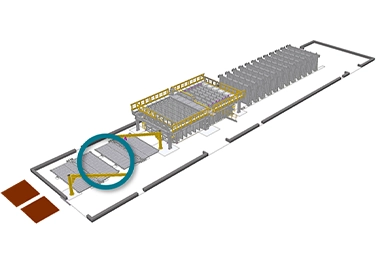

The production process with the N3P Portable Precast Plant:

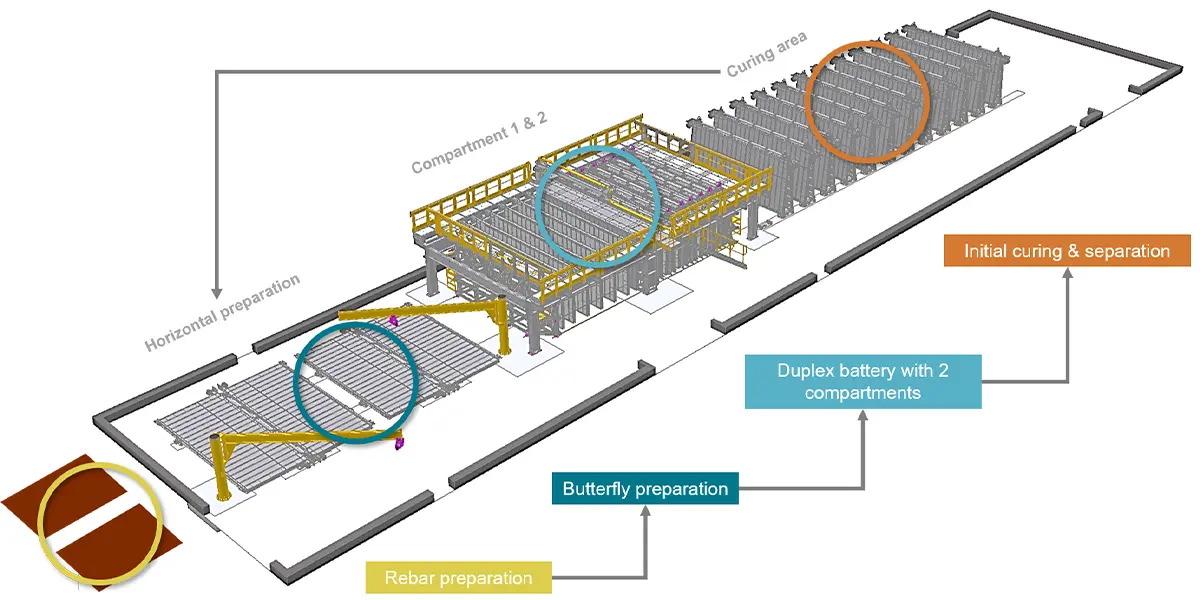

The N3P Portable Precast Plant merges construction sites and production facilities into one. The high-performance portable precast plant increases the need for a local workforce while minimising transport requirements. The plant consistently delivers the highest level of structural quality from project start to finish. Once building construction on a given project site has been completed, simply dismantle the N3P Portable Precast Plant and relocate it to the next construction site. When we developed our N3P, our aim was to implement an industrialised process at construction sites. To do this, we broke down the usual tasks of rebar preparation, closing the formwork, pouring, stripping, and curing as far as possible. The result: more efficient use of staff and a higher speed of production.

Develop valuable land with the N3P Portable Precast Plant.

Accomplish the industrialised mass production of precast concrete elements directly at the construction site with the N3P Portable Precast Plant. With its innovative butterfly technology, the plant combines the advantages of horizontal preparation with those of vertical concreting. The modular design of the production plant can thus be flexibly adapted to customer requirements.

The N3P Portable Precast Plant: the innovative tool for urban and residential planning worldwide.

How to produce precast concrete parts onsite with the N3P Portable Precast Plant.

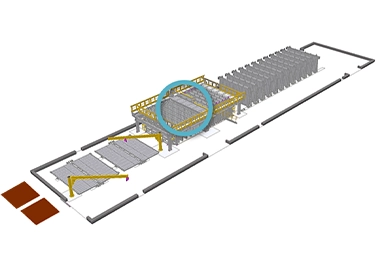

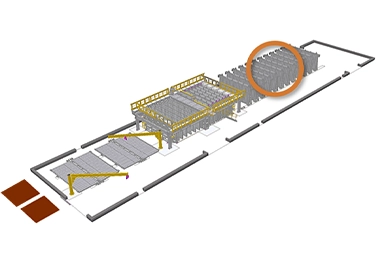

Rebar preparation

- Tie rebar cages on the rebar gauge.

Butterfly preparation

- Assemble stop-end and box-out formworks.

- Position ready-made rebar cages on the butterfly.

- Assemble inlays for electrical cables and plumbing.

Pouring

- Lift the prepared butterfly into the pouring chamber.

- Close the mould.

- Pour concrete.

- Cure the concrete for four hours initially.

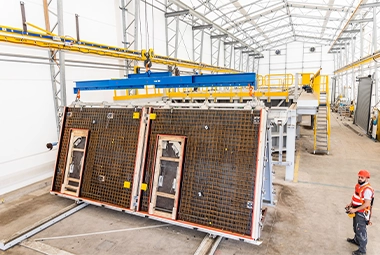

Initial curing and separation

- Lift the butterflies together with the precast elements to the curing area.

- Strip box-outs and stop-end formworks.

- Separate panels from butterflies using a crane.

Facts, figures, and advantages of the N3P Portable Precast Plant:

Global flexibility

A “plug & play” plant

Local added value

Productivity & profitability

Technical support: engineering

We can assist you with …

Technical support: operations

We can assist you with …

The N3P Portable Precast Plant drives an efficiently timed production process.

Shipping

- We ship the precast plant components to a site in 40 ordinary sea freight containers – packed and labelled in the order in which to assemble the system.

- The containers come with a simple unloading mechanism, which minimises heavy equipment usage.

- To speed operations, foundation work can begin while the equipment is being shipped, in accordance with NEULANDT’s foundation specifications.

Construction

- The plant components are erected in a specific predetermined sequence. This leads to faster assembly times with a minimum number of tasks to be completed on site.

- The plant is built in 4 to 6 weeks under the direction of a chief operating instructor, together with skilled service technicians and trained labourers.

- Depending on the size of the construction project and work scope, approximately 2 to 3 hectares of space is required for the plant, including storage areas, concrete mixing unit, the plant itself, on-site infrastructure, offices, and the necessary roads and logistics.

Training & Control

- Once the equipment has arrived, our Austrian trainers will support your team throughout the 4 to 6 week set-up period.

- After the plant has been assembled, operation of the plant is started up. Personnel are trained directly in the plant over a training period of up to three months. Installation is carried out by tower or mobile cranes available on site.

- Prior planning of every crane movement is recommended in order to minimise lost time on site. In week 7, we conduct a review of the overall building configuration and installation drawings and operational safety plans to ensure that the structure will remain stable during the construction phase.

Production

- As soon as assembly is complete, production can be ramped up.

- Output is increased shift by shift until you reach maximum productivity.

- Our trainers will accompany and support your team over an additional period of 6 to 12 weeks.

- During the ramp-up phase, the plant is being utilised, which means that panels can be used for construction or sold.

Dismantling

- When the construction project is completed, the plant can start to be dismantled, which takes approximately 4 weeks.

- Once dismantling is complete, the plant can be relocated to your next construction site.

- The plant is prepared so that it can be moved to the next construction site. Adequate barricades, warning lights, and signs to safeguard traffic in the immediate vicinity of hoisting and manoeuvring must be used.

Structural design when working with the N3P Portable Precast Plant.

Do you wish to use the N3P Portable Precast Plant to produce concrete precast elements? This is what you need to know when designing structures:

Another important tool we provide is NEULANDTcalc.

This tool enables you to estimate the cost of the whole construction project using data provided by NEULANDTengine. This means that you know how much the shell construction of a particular building will cost from the outset. You can therefore compare the cost of N3P Portable Precast Plant construction with that of other construction methods.

We recommend a grid-based design for buildings, where individual lengths combine to make a length of 6.80 m wherever possible.

Try to standardise your buildings as much as you can. In other words, use the same length of walls, and the same dimension of doors, windows, and wall openings to reduce the number of different types of elements. Consider load transfer in the structure and adopt a ‘wall-on-wall’ design. A good approach is to start the design process with the uppermost storey of a building. Further design considerations are implemented in the NEULANDTengine software, which is specially developed software tailor-made for the N3P Portable Precast Plant.

The algorithm of this software calculates relevant restrictions and criteria, such as:

The maximum size and weight of a panel, the position of components such as connectors and lifting anchors and correct distribution of the panels on the butterfly.

Like every other industrialised facility, N3P works most efficiently and profitably when used to full capacity. This means that the building structure you decide on, while expressing your individual design, needs to be aligned with the production capabilities of the plant. In order to optimise the alignment of these two elements, we have developed a design guide that covers the three most important considerations: Grid, standardisation, load transfer.